Refractory Dry out

It is well known that when you have completed a

plant repair or new build, there is usually a need

for dry out or heat up of any refractory lined installations

and components. Done correctly this can

help increase the performance & lifetime of your

refractory installations.

We can work with you to complete these services in

time and on target. We can also carry out any plant

cooling or hot hold requirements you may have.

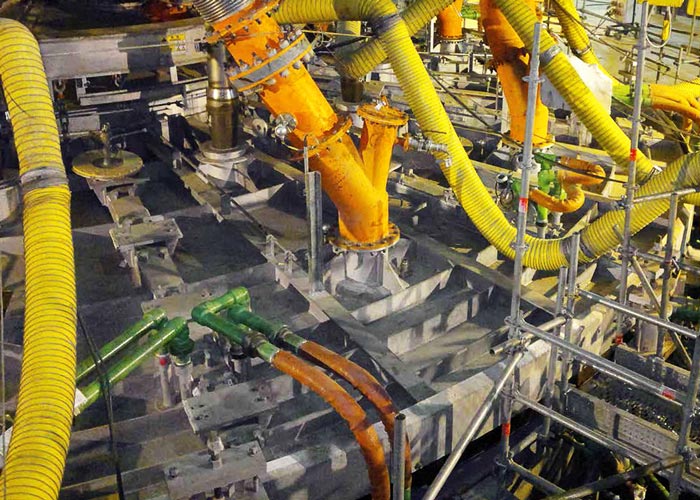

HIGH VELOCITY BURNERS

With the latest in technology, our High Velocity Burner

Units have a capacity of up to 5000 Nm3/h creating

pressure and even heat distribution throughout

your components or plant. An exceptional turndown

ratio means our burners have the capability to ensure

controlled temperature increases within the plant

that can be as little as +/- 1°C.